Dehumidifying Diseröd Pumping Station prevents corrosion

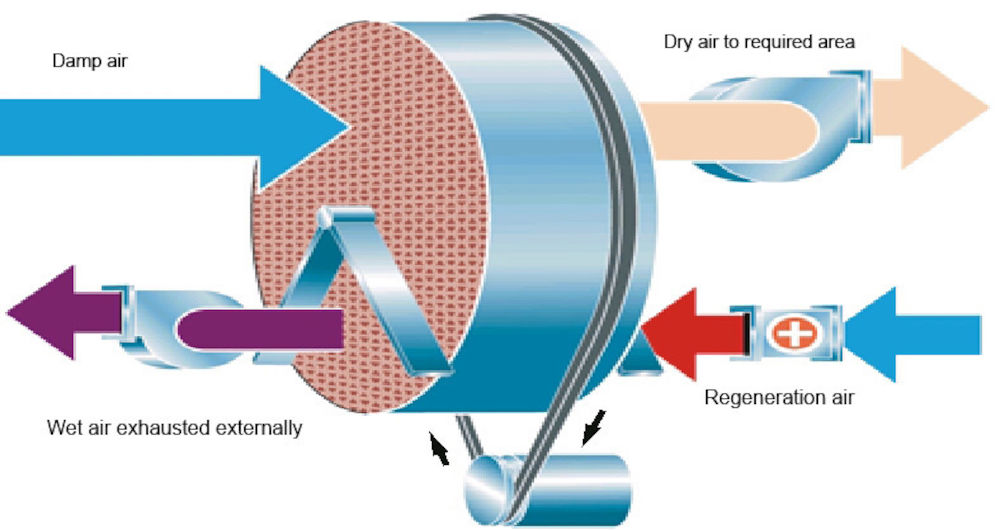

When moist air contacts a cold surface, the evaporated water in the air turns into liquid water when it condenses. By lowering the relative humidity to a level with a lower dew point, the condensation stops. This is what Munters did for Diseröd Pumping Station in Sweden.

Dehumidification of treatment plants and pumping stations is used to create a humidity-controlled climate which prevents condensation and rust.

The traditional manner of creating a better work environment is through powerful ventilation. However, there are disadvantages to this solution:

- Many of the unwanted constituents in the water are released into the air when a strong air stream is generated in the building.

- Powerful ventilation also means that the consumption of energy is dramatically increased.

It is natural for humidity to occur in a treatment plant. The humidity is largely invisible but makes its presence known when it condenses into water on walls, pipes and on other surfaces.

Since the end of the 80’s, desiccant dehumidification has been used in sewage and water treatment plants to prevent condensation. Munters’ desiccant dehumidifiers quickly generate a condensation-free climate and work effectively at any temperature, meaning the overall ventilation can be reduced dramatically and at the same time create a more comfortable and humidity-protected environment. Moreover, the consumption of energy is normally reduced by 10-20%.

With a Munter’s dehumidifier in a treatment plant or pumping station you gain:

- A more comfortable environment with a greatly reduced odour.

- Energy savings through reduced ventilation.

- A greatly reduced attack from sulphuric acid.

- Electrical equipment such as cables and contacts are protected.

- Protection for the building and electrical materials from moisture damage.

- Reduced problem with mosquitoes – a dry environment is no place for mosquitoes.

If you wish to learn more, look on www.munters.com for further details.