![AT_Case_iStock_Cheese_Medium[2].jpg](/sites/default/files/globalassets/inriver/resources/case-studies/at_case_istock_cheese_medium2.jpg)

Increase productivity with humidity control

For the dairy industry the dry winter climate is preferable as drying processes, conveyors and hygroscopic products absorb less or no humidity from the ambient air. This means processes are faster, uninterrupted and the risk of mold is reduced.

Moreover, the moisture causes corrosion problems in electrical and electronic equipment. A dry climate is, therefore, highly recommended to avoid these problems.

To maintain constant environmental conditions all year round, Munters dry injected air in entrance of the tower to ensure a constant and low absolute humidity. With Munters dehumidification systems can reduce energy capacity by 20-25% for the same level of production.

Fluidized Bed

In many cases, products that require cooling are dried again. This refers to products containing fats and which can become rancid. The cooling phase is performed efficiently using the fluidized bed driers. To prevent absorption of moisture by the product from the cooled air, the air should be dehumidified.

Pneumatic Conveying

In a pneumatic conveying system, the contact between the air and conveyed product is very close which means that a dried powders can reabsorb humidity if the conveying air is humid. To prevent this pneumatic conveying systems are equipped with dehumidifiers to keep raw materials fast flowing and free from sticking and caking.

Baghouses

The air contains particles that are filtered through the process before going abroad. During phases of stoppage, the hygroscopic product added to the filter can absorb moisture and, therefore, clog the filter. With Munters dehumidification systems the internal filter stays dry, even when standing.

Cheese drying and storage

In a storage room kept cool by air circulating through an air cooler, condensation on cooling surfaces is common. Often the relative humidity exceeds 70%RH at which point there is a risk of mold. The solution is desiccant dehumidification which is equally efficient at all temperatures and helps maintain cheese quality.

Dried before packing

Some types of cheese need to dry completely, before the coating phase. For effective drying without increasing temperature, Munters dehumidification systems are the perfect solution.

Drying after clean downs

When cleaning with water the drying process can be accelerated with dehumidified air, reducing the risk of mould and bacterial growth. Dehumidified air can be blown into the room where equipment has been cleaned so prolonging the cleaning intervals and reducing cleaning costs.

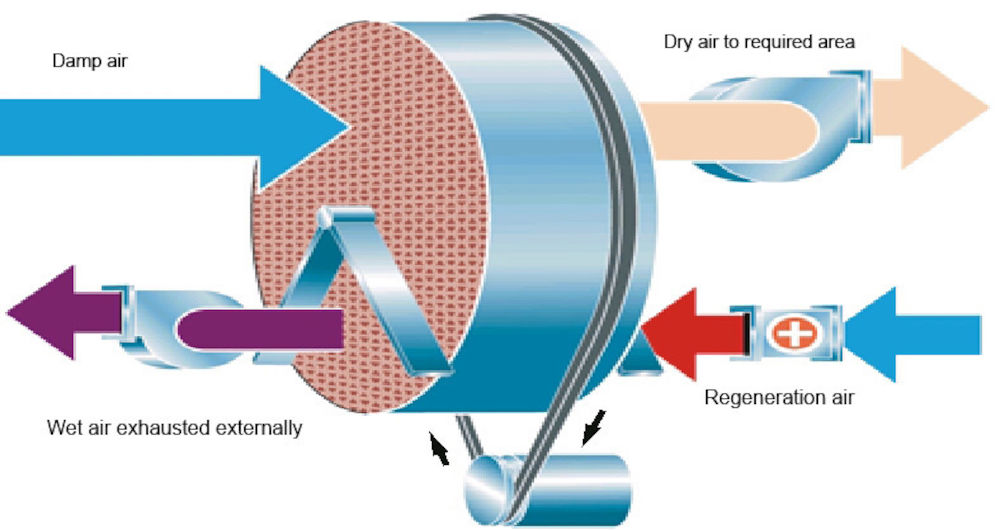

Munters desiccant dehumidifiers work by passing moist air from the process or store through a slowly revolving desiccant wheel. The resulting dry air is pumped into the store, conveyor, spray tower or silo, allowing products to flow freely and increasing drying efficiency.